David1226

Registered

Gernise End Station on the Claptowte Railway was in need of a goods loading dock and a cattle loading dock. I had a broad idea of the size and the look of these structures but was not sure about the materials I should use. The decision was made when I constructed a platform on which to place the stations yard crane. This was constructed using a carcase of 3.0mm plywood, reinforced using short lengths of square section strip wood. The top was made of 3.0mm thick plasticard sheet which was scribed and carved to represent stone slabs. The sides were clad with 1/24th scale embossed textured brick paper. I was very pleased with the results, so the die was cast when it came to building the loading docks. I started both docks in tandem as although they were slightly different shapes and dimensions, the construction methods and materials were the same up until the ‘fitting out’ of the tops.

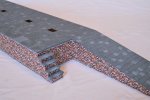

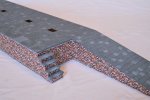

The first pictures show the basic plywood carcase.

Next photos showed the ramp and steps attached. The steps are fabricated from plasticard sheet.

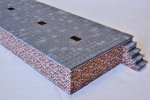

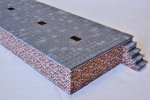

The top surface of the dock is formed from 3.0mm thick plasticard sheet scribed and carved to represent paving stones/tiles.

The gullies were drilled out and the sides filed square. The holes were framed out with plasticard strips of appropriate size. The gulley tops were cut from expanded aluminium mesh as used to reinforce automobile repairs.

Before the plasticard tops were glued on top of the plywood carcase, the areas below where the gullies are positioned were painted matt black. The plasticard tops were painted before being glued on, as were the treads of the steps. After gluing on the tops, the sides of the dock were covered with the same 1/24th scale embossed textured brick paper that I used on the platform for the yard crane. When this was done, the step treads were glued in place. That completed the basic structure.

I have added some wooden battens to the ramp to stop the beasties slipping and sliding when the slope is wet and slippery. The battens are cut from wooden coffee stirrers and stained with dilute black paint. The bolt heads are 1.0mm self adhesive pearl gems.

The next task was the posts for the stock fencing. The posts are lengths of 10.0mm square strip wood purchased from eBay. A hole was drilled vertically into each base and a short length of wire rail was glued in to form a peg. A corresponding hole was drilled at the appropriate location in the decking into which the peg could be glued. Each post will support five rails. I made a jig from scrap plasticard to ensure that, when drilled, all holes were correctly spaced and that the rails would line up. Gate hinges where created from plastic tube and garden wire. The posts were then given a couple of coats of matt white. The posts here are not yet fixed, just posed for the photograph. Before fixing any posts/rails I also drilled two holes in the deck to take a pair of lamp posts, one in each cattle pen.

The stock rails were added from 1.6mm bronze brazing wire, also purchased from eBay, and the posts were glued in position at the same time. Handrails were also added to the steps at each end of the dock.

I then had to construct five pairs of gates. These were constructed from various tubes and strips of plasticard as well as rails and bolts from bronze wire. The vertical components are square plasticard tube. I again made a jig out of scrap plasticard to ensure that all of the drilled holes, for the rails, were in the right locations.

A. The prepared component parts ready for gluing together.

B. An assembled gate

C. A completed pair of gates ready for painting.

Closed and open painted gates installed

An addition to the dock is a hose for washing down the pens and hosing out any cattle wagons after unloading. The hose is connected to a three way stand pipe with taps for filling of the two water troughs in the cattle pens. The hose is a length of green garden wire. The pipe stand is made from lengths of 2.5mm mains cable and is lagged with windings of narrow strips of masking tape. The taps and connectors are bits of wire insulation. The support for the standpipe and the crosspiece, to hold the hose, are strips of plasticard.

David

The first pictures show the basic plywood carcase.

Next photos showed the ramp and steps attached. The steps are fabricated from plasticard sheet.

The top surface of the dock is formed from 3.0mm thick plasticard sheet scribed and carved to represent paving stones/tiles.

The gullies were drilled out and the sides filed square. The holes were framed out with plasticard strips of appropriate size. The gulley tops were cut from expanded aluminium mesh as used to reinforce automobile repairs.

Before the plasticard tops were glued on top of the plywood carcase, the areas below where the gullies are positioned were painted matt black. The plasticard tops were painted before being glued on, as were the treads of the steps. After gluing on the tops, the sides of the dock were covered with the same 1/24th scale embossed textured brick paper that I used on the platform for the yard crane. When this was done, the step treads were glued in place. That completed the basic structure.

I have added some wooden battens to the ramp to stop the beasties slipping and sliding when the slope is wet and slippery. The battens are cut from wooden coffee stirrers and stained with dilute black paint. The bolt heads are 1.0mm self adhesive pearl gems.

The next task was the posts for the stock fencing. The posts are lengths of 10.0mm square strip wood purchased from eBay. A hole was drilled vertically into each base and a short length of wire rail was glued in to form a peg. A corresponding hole was drilled at the appropriate location in the decking into which the peg could be glued. Each post will support five rails. I made a jig from scrap plasticard to ensure that, when drilled, all holes were correctly spaced and that the rails would line up. Gate hinges where created from plastic tube and garden wire. The posts were then given a couple of coats of matt white. The posts here are not yet fixed, just posed for the photograph. Before fixing any posts/rails I also drilled two holes in the deck to take a pair of lamp posts, one in each cattle pen.

The stock rails were added from 1.6mm bronze brazing wire, also purchased from eBay, and the posts were glued in position at the same time. Handrails were also added to the steps at each end of the dock.

I then had to construct five pairs of gates. These were constructed from various tubes and strips of plasticard as well as rails and bolts from bronze wire. The vertical components are square plasticard tube. I again made a jig out of scrap plasticard to ensure that all of the drilled holes, for the rails, were in the right locations.

A. The prepared component parts ready for gluing together.

B. An assembled gate

C. A completed pair of gates ready for painting.

Closed and open painted gates installed

An addition to the dock is a hose for washing down the pens and hosing out any cattle wagons after unloading. The hose is connected to a three way stand pipe with taps for filling of the two water troughs in the cattle pens. The hose is a length of green garden wire. The pipe stand is made from lengths of 2.5mm mains cable and is lagged with windings of narrow strips of masking tape. The taps and connectors are bits of wire insulation. The support for the standpipe and the crosspiece, to hold the hose, are strips of plasticard.

David

Last edited: