Madman

Registered

I am in the process of building a lift bridge for my Lionel "O" gauge layout. It will connect two peninsulas. It will rise from table top to a height that a person can walk under. I'd like to install limit switches so that when the bridge reaches its upper or lower position, it will stop, even if I have my hand on the DPDT momentary switch.

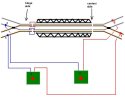

I have several of those tiny roller switches, similar to these.....

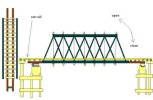

The bridge design, rough sketch.....

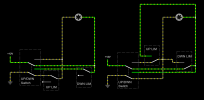

And the start of a wiring diagram.....

I need to complete the wiring diagram, but am stuck.....Please help !

I have several of those tiny roller switches, similar to these.....

The bridge design, rough sketch.....

And the start of a wiring diagram.....

I need to complete the wiring diagram, but am stuck.....Please help !