John Russo

Registered

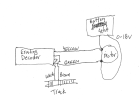

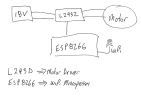

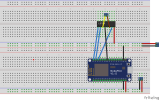

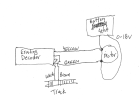

I am working on powering a loco with battery.

I am in the prototype phase and considering using a loco that currently has a Massoth DCC decoder installed and direct wired to the motor.

If I wish to leave the decoder installed while I test this, will it damage the decoder if I put 18v to the motor while the decoder is still connected?

Anyone know if the Massoth have protective circuitry to allow this?

If not, I will disconnect the decoder.

I am in the prototype phase and considering using a loco that currently has a Massoth DCC decoder installed and direct wired to the motor.

If I wish to leave the decoder installed while I test this, will it damage the decoder if I put 18v to the motor while the decoder is still connected?

Anyone know if the Massoth have protective circuitry to allow this?

If not, I will disconnect the decoder.