There was a thread about these some time back.

www.gscalecentral.net

I have had a sort of long time longing for one but never got round to buying one before they went off the market for a while.

www.gscalecentral.net

I have had a sort of long time longing for one but never got round to buying one before they went off the market for a while.

They appear to be available again, though may never have been unavaiable!

www.swiftsixteen.co.uk

www.swiftsixteen.co.uk

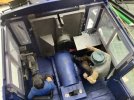

I got mine through an add in the 16mm Journal, built at a good knock down price. As it had a Plane type of RC I asked for that to not be included also the speed control which was not the sort that I like. So when the beast arrived I put it on the track and had a good look.

Hm tricky to fit RC without filling the compartments. Also not having built the kit I am u sure of the parts makeup, certainly theH roof was well attached and possibly moulded in 1 part with the front and sides.

EDIT just looked at the instructions and yes the body os a 1 part mould.

Thus it sat on the workbench while the Flexicity Tram was being faffed about with.

Much thought was to be involved with fitting a MLS Sould Unit and Rx n Speed Control.

To be continued….

Swiftsixteen railcars

Has built these? They look good. Can get one as unpowered to run with the other as the power car? Thanks

They appear to be available again, though may never have been unavaiable!

Railbus | Mysite

PLEASE NOTE, This kit is out of stock as the expensive mould has worn out. We will/can remake the mould, but need pre-orders first to justify the re-tooling cost. We need 5 pre-orders. There are models placed 'instock' and we will update this counter as each pre-order is sold. When all 5 are...

www.swiftsixteen.co.uk

www.swiftsixteen.co.uk

I got mine through an add in the 16mm Journal, built at a good knock down price. As it had a Plane type of RC I asked for that to not be included also the speed control which was not the sort that I like. So when the beast arrived I put it on the track and had a good look.

Hm tricky to fit RC without filling the compartments. Also not having built the kit I am u sure of the parts makeup, certainly theH roof was well attached and possibly moulded in 1 part with the front and sides.

EDIT just looked at the instructions and yes the body os a 1 part mould.

Thus it sat on the workbench while the Flexicity Tram was being faffed about with.

Much thought was to be involved with fitting a MLS Sould Unit and Rx n Speed Control.

To be continued….