Madman

Registered

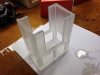

I picked up a USA Trains 44 ton loco recently. It was a half completed repaint, but like new otherwise. Since I run battery power, I dismantled the loco and removed the electronics. In the process I removed the pick-up skates, thin spring wire contacts inside each motor block and cut the wires that were soldered to the journals.

All went according to Hoyle until I tried to reassemble the motor block lower covers. What a PITA that was. There are brass bearings that are square-ish. These fit into the upper portion of the motor blocks as well as the lower portion. Because of the sprung side frames, the axles kept pushing up, causing the brass bearings to turn so that they would not stay in the slots allotted for them. Each time I very carefully aligned the bearings with the slots in the upper motor block casting, then tried putting the lower motor block cover on, the bearings would move or turn slightly. This prevented the lower motor block cover from seating.

After a few attempts with each motor block, I finally was successful. Having only two hands and ten fingers was a handicap to the process.

Has anyone else dismantled and reassembled one of these beasts ? If so, is there a secret code to use to make reassembly easier ?

All went according to Hoyle until I tried to reassemble the motor block lower covers. What a PITA that was. There are brass bearings that are square-ish. These fit into the upper portion of the motor blocks as well as the lower portion. Because of the sprung side frames, the axles kept pushing up, causing the brass bearings to turn so that they would not stay in the slots allotted for them. Each time I very carefully aligned the bearings with the slots in the upper motor block casting, then tried putting the lower motor block cover on, the bearings would move or turn slightly. This prevented the lower motor block cover from seating.

After a few attempts with each motor block, I finally was successful. Having only two hands and ten fingers was a handicap to the process.

Has anyone else dismantled and reassembled one of these beasts ? If so, is there a secret code to use to make reassembly easier ?