FatherMcD

Registered

The title isn't exactly my actual question, but I kept it since it was referred to in my earlier thread "Any Experience with a DC step up module?"

Let me describe my situation. I have two PIKO 25tonners.

Engine #1: PIKO factory R/C. 6 AAA batteries. Ran fine, longer life with Alkalines than NiMh, as to be expected. I added MLS card and it worked well, except, that as the batteries ran down, pressing a horn button would cause the loco to stop dead, as in a screeching halt and the sounds stopped. Not good for the gear train! (I believe I mentioned this on another thread.) I'm in the process of squeezing a 4x18650 battery pack wired for 7.4v in this loco in hopes that the slightly higher voltage and current available would prevent the problem. I'm waiting for a part to complete this installation. Talk about a slow boat to China...three months! Importantly, the sound trigger wires from the PIKO board were connected to the two terminals on the right in the attached diagram. I didn't have this diagram at the time of the installation. Also, this MLS didn't have the bell sound.

Then in February of '21 PIKO support told me that they were developing a sound card for the 25tonner which would be available by the c-word 2021.

So, I bought ;

Engine #2: PIKO factory track power. Ran nicely on track power. I converted this to R/C using the PIKO 35040, same board as the factory R/C. I had planned to add the upcoming PIKO sound board with the bell sound to this loco, however while locos with factory R/C and sound are finally available, add-on sound boards are still several months out according to PIKO customer support. Price not determined, but the cheapest current sound upgrade for other locos is US$170.

Price not determined, but the cheapest current sound upgrade for other locos is US$170.

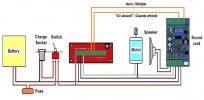

So, I decided to add the new MLS with the bell sound using the diagram attached. (Courtesy of Peter Lucas) Ah ha, perhaps my screeching halt problem was caused by my incorrect wiring. I consider myself lucky that there was no blue smoke in Engine #1.

So, I decided to add the new MLS with the bell sound using the diagram attached. (Courtesy of Peter Lucas) Ah ha, perhaps my screeching halt problem was caused by my incorrect wiring. I consider myself lucky that there was no blue smoke in Engine #1.

However, I now have the same basic problem;

(Note that the following voltage measurements are of the voltage available at the battery pack under NO load. i.e. removed from the loco. They would almost certainly be lower if I could easily measure under load. My concern is for the relative minimum voltages.)

A. With 6xAAA Alkaline, providing 9.59 volts, switch power on, cab light comes on. Press forward button, engine sound starts and loco moves forward and accelerates with additional button presses. This runs fine for about 50 min. then abruptly stops with sound still on. Voltage measures 8.23.

B. With 6xAAA NiMh, providing 7.72 volts, power on, cab light on, press forward button, engine sound starts but forward headlight only comes on for about a second and the loco doesn't move. Since this loco stops at 8.23v, it is obvious why it won't start at 7.72v. (Hmm. With my incorrect wiring of the MLS in Engine #1, it would run with the 6xAAA NiMh. I don't have any voltage measurements for that setup. Strange )

)

PIKO sound boards aren't even available yet, so the answer to the thread title is MLS, at least for now. Of course, I could wait for the PIKO sound card to become available, but that is likely to take several more months and cost about US$70 more. For now, the real question is how to prevent the abrupt stopping. As an aside, I will be switching Engine #2 to Li-Ion for greater run time and to match my Li-Ion standard. The Stock PIKO 6xAAA packs allow me to experiment because they run out of power quicker. Battery type, size, capacity and placement aren't the issue at this time (I hope)

According to PIKO documentation, the 35040 specs call for 7-24 VDC. According to Peter the minimum voltage for the MLS is 7.2V. My testing indicates the MLS will still function at a relatively lower voltage than the 35040 when they are operating in parallel. I want to "reverse" that so the MLS stops producing sound, indicating that the battery is low, before the 35040 shuts down and locks up the drive train.

My hope is that adding a DC-to-DC step up convertor between the battery and the 35040, set to about 9V output, will allow the 35040 to continue to operate when the voltage to the MLS drops below it's operating threshold.

If you have made it this far, thanks for your interest. Any observations, thoughts, questions before I go to the time and expense of this experiment?

Let me describe my situation. I have two PIKO 25tonners.

Engine #1: PIKO factory R/C. 6 AAA batteries. Ran fine, longer life with Alkalines than NiMh, as to be expected. I added MLS card and it worked well, except, that as the batteries ran down, pressing a horn button would cause the loco to stop dead, as in a screeching halt and the sounds stopped. Not good for the gear train! (I believe I mentioned this on another thread.) I'm in the process of squeezing a 4x18650 battery pack wired for 7.4v in this loco in hopes that the slightly higher voltage and current available would prevent the problem. I'm waiting for a part to complete this installation. Talk about a slow boat to China...three months! Importantly, the sound trigger wires from the PIKO board were connected to the two terminals on the right in the attached diagram. I didn't have this diagram at the time of the installation. Also, this MLS didn't have the bell sound.

Then in February of '21 PIKO support told me that they were developing a sound card for the 25tonner which would be available by the c-word 2021.

So, I bought ;

Engine #2: PIKO factory track power. Ran nicely on track power. I converted this to R/C using the PIKO 35040, same board as the factory R/C. I had planned to add the upcoming PIKO sound board with the bell sound to this loco, however while locos with factory R/C and sound are finally available, add-on sound boards are still several months out according to PIKO customer support.

However, I now have the same basic problem;

(Note that the following voltage measurements are of the voltage available at the battery pack under NO load. i.e. removed from the loco. They would almost certainly be lower if I could easily measure under load. My concern is for the relative minimum voltages.)

A. With 6xAAA Alkaline, providing 9.59 volts, switch power on, cab light comes on. Press forward button, engine sound starts and loco moves forward and accelerates with additional button presses. This runs fine for about 50 min. then abruptly stops with sound still on. Voltage measures 8.23.

B. With 6xAAA NiMh, providing 7.72 volts, power on, cab light on, press forward button, engine sound starts but forward headlight only comes on for about a second and the loco doesn't move. Since this loco stops at 8.23v, it is obvious why it won't start at 7.72v. (Hmm. With my incorrect wiring of the MLS in Engine #1, it would run with the 6xAAA NiMh. I don't have any voltage measurements for that setup. Strange

PIKO sound boards aren't even available yet, so the answer to the thread title is MLS, at least for now. Of course, I could wait for the PIKO sound card to become available, but that is likely to take several more months and cost about US$70 more. For now, the real question is how to prevent the abrupt stopping. As an aside, I will be switching Engine #2 to Li-Ion for greater run time and to match my Li-Ion standard. The Stock PIKO 6xAAA packs allow me to experiment because they run out of power quicker. Battery type, size, capacity and placement aren't the issue at this time (I hope)

According to PIKO documentation, the 35040 specs call for 7-24 VDC. According to Peter the minimum voltage for the MLS is 7.2V. My testing indicates the MLS will still function at a relatively lower voltage than the 35040 when they are operating in parallel. I want to "reverse" that so the MLS stops producing sound, indicating that the battery is low, before the 35040 shuts down and locks up the drive train.

My hope is that adding a DC-to-DC step up convertor between the battery and the 35040, set to about 9V output, will allow the 35040 to continue to operate when the voltage to the MLS drops below it's operating threshold.

If you have made it this far, thanks for your interest. Any observations, thoughts, questions before I go to the time and expense of this experiment?

Attachments

Last edited: