BakerJohn

Baker, Modeler, future husband

Good Morning all!

I would like to share with you my new project since my Forney is (almost) complete! I am going to be rewiring and detailing Bachmann's LS Toby the Tram. The goals of this project are to:

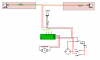

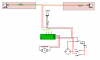

Here's my wiring diagram for the loco...

There's a DPDT switch on the bottom of these locos used to switch polarity (or polabity). But, I'll be rewiring it to basically use it as a SPDT to switch between run and charge. You'll notice that the lights are also directly connected to the switch, but only the inside one will be always on when the locomotive is switched to RUN. (I need something to tell me the battery is active. Since there's no sound with this one I thought a cab light would be good.)

I've taken measurements of the whole thing and figured out what parts I need for this project already. However, I'm probably not going to really start until there's no chance of getting outside again. At the moment I may still be able to do some track work...

I would like to share with you my new project since my Forney is (almost) complete! I am going to be rewiring and detailing Bachmann's LS Toby the Tram. The goals of this project are to:

- rewire for battery power r/c control including lights

- remove the eye mechanism

- remove all black-out windows and doors

- glaze windows

- fit floors and walls in cab

- fabricate boiler to cover motor block and hie battery, Rx, and wiring

- fabricate new brass hand rails

- fabricate new light fixtures for either end of the tram

Here's my wiring diagram for the loco...

There's a DPDT switch on the bottom of these locos used to switch polarity (or polabity). But, I'll be rewiring it to basically use it as a SPDT to switch between run and charge. You'll notice that the lights are also directly connected to the switch, but only the inside one will be always on when the locomotive is switched to RUN. (I need something to tell me the battery is active. Since there's no sound with this one I thought a cab light would be good.)

I've taken measurements of the whole thing and figured out what parts I need for this project already. However, I'm probably not going to really start until there's no chance of getting outside again. At the moment I may still be able to do some track work...