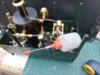

Well I finally managed to get Otto running today. My worries about Water were probably over the top. In any case I managed to source a Regner Water Top Up system from Martins Models at the 16mm bash at Peterborough last week. The fitting of this could upset the novce as you need to bend the Long Pipe twice, drill a hole to fit to the Chassis Plate and Silver Solder a Nipple onto the pipe at the end where it fits to the Barrell. I found all of this quite manageable, but I guess many would not.

I fitted mine ontop of the Gauge Glass as this helps to wash down crud that could sit there and make Water Level much better to view.

On first run, and I have only run it the once it was very controllable. This is to be expected with Live Steam Geared Locomotives. I would put it on a par with my Angus Machines, though not in Build or Quietness of running. Verily Otto is a very noisy little beast, but that to me adds to the charm. You certainly know he is on the move.

Must to a Vid soon.

Thanks for your help and thoughts guys.

JonD

I fitted mine ontop of the Gauge Glass as this helps to wash down crud that could sit there and make Water Level much better to view.

On first run, and I have only run it the once it was very controllable. This is to be expected with Live Steam Geared Locomotives. I would put it on a par with my Angus Machines, though not in Build or Quietness of running. Verily Otto is a very noisy little beast, but that to me adds to the charm. You certainly know he is on the move.

Must to a Vid soon.

Thanks for your help and thoughts guys.

JonD