ge_rik

British narrow gauge (esp. Southwold and W&LLR)

I've decided to put this in the thread in the scratchbuild section as it's not purely 3D printing - I'm just using 3D printing as part of the process, albeit a fairly significant part.

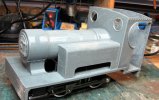

After deciding to use a Bachmann Lyn motor block as the basis for a Schull & Skibbereen loco build, a couple of fellow modellers generously sent me a couple of their redundant Lyn motor blocks, one of which was from the more recent version. It required a bit of remediation; new wheels (the flanges were worn flat in a couple of places), a new motor and new motion - but result is a rather fine motor block - far better engineered and powerful than the old mechanism!

After searching the web for a suitable 4-coupled loco I could place on top of the chassis, I hit upon the Kerr Stuart Skylark locos. Although there was a basic design, they produced quite a few variations - the one which appealed to me was the Metropolitan Water Board locos - which I felt could easily have been adapted to run on three foot metals.

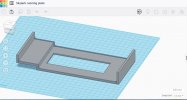

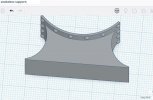

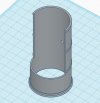

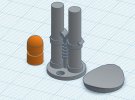

All I needed to do was draw and print the parts needed ........

Rik

After deciding to use a Bachmann Lyn motor block as the basis for a Schull & Skibbereen loco build, a couple of fellow modellers generously sent me a couple of their redundant Lyn motor blocks, one of which was from the more recent version. It required a bit of remediation; new wheels (the flanges were worn flat in a couple of places), a new motor and new motion - but result is a rather fine motor block - far better engineered and powerful than the old mechanism!

After searching the web for a suitable 4-coupled loco I could place on top of the chassis, I hit upon the Kerr Stuart Skylark locos. Although there was a basic design, they produced quite a few variations - the one which appealed to me was the Metropolitan Water Board locos - which I felt could easily have been adapted to run on three foot metals.

All I needed to do was draw and print the parts needed ........

Rik