Eaglecliff

Registered

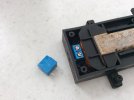

One of mine has failed. The ammeter tells me there is no current passing between the terminals, although the wires between the terminals and the coil appear to be ok, as does the coil itself. Any suggestions as to:

possible cause of problem;

possible cure;

possible source of replacement parts?

I am assuming that there is actually no cure, replacement being the only answer, but I thought I'd ask. With current price about 50% above what I remember paying for the most recent ones, it's always worth a try.

possible cause of problem;

possible cure;

possible source of replacement parts?

I am assuming that there is actually no cure, replacement being the only answer, but I thought I'd ask. With current price about 50% above what I remember paying for the most recent ones, it's always worth a try.