Greg Elmassian

Guest

Picture please! Carriers are always interesting. The big live steam guys have them custom made.

Picture please! Carriers are always interesting. The big live steam guys have them custom made.

Yes cassette is well picked.

So, I would think the idea of cassettes would top out around HO scale.

Thank you for explaining. Have not seen this in the US except for train storage, like a wall module.

I have seen ones that have foam on the top to keep the train on the "tracks"

Greg

Something like a sprung bollard which lifts as the bridge is raisedAlways a good idea, but for the battery folk, you need a physical obstruction.

Something like a sprung bollard which lifts as the bridge is raised

Rather than cutting the excess off.. How about bending it down, to give additional rigidity?

The gap needed to allow opening is not really that wide it is slightly wider than the thickness of the board.

did you calculate the thickness of the board PLUS the height of track?

(plus a little additional, that the board can be turned up more than 90°, to stay open without any hook?)

(plus enough space, that your upturned track on the board does not push against the points of the fixed rails leading to the bridge?)

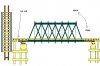

I'm a bit confused, if the bridge is level with the baseboard, won't the addition of the actual bridge be higher... but I'm happy to wait for pictures... still a bit skeptical of clearances, thinking you might have to play with location of hinge point, but again, happy to wait for progress pictures.

Greg