Mark Janzen

G Scale Layout

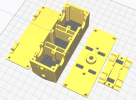

I have a narrow gauge 1:20.3 Accucraft electric 2-truck Shay #2. The existing pot metal frames on both of the trucks are damaged beyond repair. I would like to 3D print new truck frames and use the existing gearing and drive shafts. I only know how to use TinkerCad and TinkerCad is not sophisticated enough to design the required STL files for my PRUSA printer. Due to 3D printer filament structural limitations,I realize the new plastic truck frames will need to be more robust and not true to original truck designs . Does anyone know where I can find suitable shay truck design STL files? I'm willing to "tweak" a related Shay truck designed. Any help would be appreciated.