Greg Elmassian

Guest

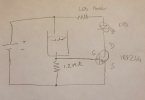

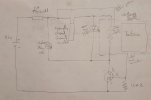

Nice, the PolySwitch (it's not really called a polyfuse strangely) PolySwitch Resettable PTCs Devices - Littelfuse is a nice resettable device.

If you look carefully you can get ones that have tighter tolerances, but while for sudden shorts, you rate like a regular fuse (trips at 200%), at constant loads that don't spike a lot, they trip pretty colse to the rating.

The "thermocouple" is really a thermal switch, right? So on off should yield pretty much full voltage... are you going to use 20 ohms on the resistor? If so, max amps of about 0.74 would mean a 2 amp Polyswitch might bet technically better, I doubt you will get much of an inductive "kick" at this current and voltage, even though the resistor is indeed wirewound.

Nice idea, and the only question is what duty cycle will be necessary to keep it "warm".

An interesting solution to a common issue.

Greg

If you look carefully you can get ones that have tighter tolerances, but while for sudden shorts, you rate like a regular fuse (trips at 200%), at constant loads that don't spike a lot, they trip pretty colse to the rating.

The "thermocouple" is really a thermal switch, right? So on off should yield pretty much full voltage... are you going to use 20 ohms on the resistor? If so, max amps of about 0.74 would mean a 2 amp Polyswitch might bet technically better, I doubt you will get much of an inductive "kick" at this current and voltage, even though the resistor is indeed wirewound.

Nice idea, and the only question is what duty cycle will be necessary to keep it "warm".

An interesting solution to a common issue.

Greg