Gavin Sowry

Garden Railroader and Raconteur

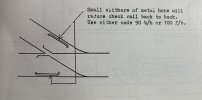

Points are a component part of a turnout. They are the skinny rails at the start, that, strangely, are ground down to a point, hence the name. Turnout is the universally accepted name for this type of track structure... even the Americans (real railroad types, not the train nutters) are (slowly) coming around to this terminology.Funny, I was researching terms on a UK site, and I found "turnouts" used in modern prototype documents as much or more than "points".