Building your own track is certainly a worthwhile occupation when you have lots of points or near points (interlaced) required. You certainly save a great deal of wad a d get something that is not supplied commercially to boot. There was a time where it was not worthwhile to build plain track from scratch but I am not sure how the costs stack up now.

In any case looking at what Dave is doing on the kitchen table, I would have thought a good sized piece of Melamine would work for points being able to take it on and off the kitchen table with part built bits of track as ordered? I had a jig that I made when building 0 gauge track many moons ago that still lives in my loft for the day when I may get back into 0 gauge again, was on a length of chipboard that has seen many points built including 3 way and ‘nearly a slip NAS’. NAS was actually 2 interlaced points that I saw as a prototype at Chichester in my Selsey Light Railway book.

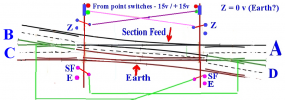

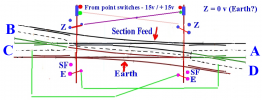

As you can see most of the routes from a slip are possible. But C-D is not without a triple shunt C-B, B-A, A-D.

View attachment 288941