You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Playmobil Turntable

- Thread starter Polarblair

- Start date

Polarblair

Registered

I was hoping that would be the case. So for the time being automation is probably a step too far which would keep things simpler. Ball spring plunger and detent indexing might be the way to go as an off the shelf solution.Automation and RC do not fit overly well..

Using RC to send commands via a proprietary system can be done, but not normally route selection.

Buffer stop. Shuttle, and Station stop, are available.

PhilP

Cobalt6700

Registered

Controlling a turntable with a stepper motor and an Arduino based system is fairly easy to do. An example from DCC-EX:

Overview — DCC-EX Model Railroading documentation

Interfacing this with some sort of RC controller would also be fairly trivial.

There are a number of DIY turntable projects out there, most of them use stepper motors (same as you find on a 3D printer).

Model Electronics Railway Group do a turntable controlller kit which is around £16+P&P

That would also be fairly easy to automate with RC, either using a RC setup or Arduino.

Overview — DCC-EX Model Railroading documentation

Interfacing this with some sort of RC controller would also be fairly trivial.

There are a number of DIY turntable projects out there, most of them use stepper motors (same as you find on a 3D printer).

Model Electronics Railway Group do a turntable controlller kit which is around £16+P&P

That would also be fairly easy to automate with RC, either using a RC setup or Arduino.

Madman

Registered

I was hoping that would be the case. So for the time being automation is probably a step too far which would keep things simpler. Ball spring plunger and detent indexing might be the way to go as an off the shelf solution.

View attachment 318567

They look like an excellent solution. Especially in keeping with the KISS method, which I subscribe to. I'll have to do a search for tiny versions of these, for use on my "O" gauge sector plate.

Or, maybe delve into some sort of tiny infra-red devices. Maybe even tiny magnets that would help align the tracks with a bit more preciseness than doing it by eye.

An early video of my sector plate;

playmofire

Registered

If you do go down the infrared route, I have some spare, unused sensors that need a home.

Polarblair

Registered

That looks properly smart! Not sure why I didn't jump to magnets first to be honest as I've used small neodymium magnets in lots of projects. Only downside to them is that they like to be oriented correctly on their axis or you substantially reduce their effectiveness.They look like an excellent solution. Especially in keeping with the KISS method, which I subscribe to. I'll have to do a search for tiny versions of these, for use on my "O" gauge sector plate.

Or, maybe delve into some sort of tiny infra-red devices. Maybe even tiny magnets that would help align the tracks with a bit more preciseness than doing it by eye.

An early video of my sector plate;

I used a bunch on a sliding lid that I wanted to have two open positions but didn't think of the orientation. Glued all the magnets in and only realised after. Kind of still worked but not nearly as well.

Polarblair

Registered

Now that MERG kit looks just the ticket. Has anyone got a purchace link for 79C? I believe that's the version of the turntable kit that comes with the switches and just needs the stepper motor purchased separately.Controlling a turntable with a stepper motor and an Arduino based system is fairly easy to do. An example from DCC-EX:

Overview — DCC-EX Model Railroading documentation

Interfacing this with some sort of RC controller would also be fairly trivial.

There are a number of DIY turntable projects out there, most of them use stepper motors (same as you find on a 3D printer).

Model Electronics Railway Group do a turntable controlller kit which is around £16+P&P

That would also be fairly easy to automate with RC, either using a RC setup or Arduino.

Or is it that you need to be a MERG member to purchase kits?

I don't think that's right as WM collectibles seem to sell quite a few MERG kits:

W M Collectables

Cobalt6700

Registered

Now that MERG kit looks just the ticket. Has anyone got a purchace link for 79C? I believe that's the version of the turntable kit that comes with the switches and just needs the stepper motor purchased separately.

Or is it that you need to be a MERG member to purchase kits?

I don't think that's right as WM collectibles seem to sell quite a few MERG kits:

W M Collectables

wmcollectables.co.uk

No problems.

You will need to be a MERG member to purchase - or as you have found, someone who resells MERG kits.

I would recommend becoming a MERG member as you will have access to all of the information and support - plus there is a revised PCB design and firmware.

The way MERG works - if you buy a kit from them you will get support, if you buy from a reseller you will have to seek support through the seller.

Madman

Registered

Just did a search for MERG. Looks like an excellent site for a non-electronic-believer, myself being one. I was able to download Davy Dick's book. From what I have seen so far, it appears to be written so that people like me can gain an understanding of basic electronics and their practical use in our railways.

Cobalt6700

Registered

Just did a search for MERG. Looks like an excellent site for a non-electronic-believer, myself being one. I was able to download Davy Dick's book. From what I have seen so far, it appears to be written so that people like me can gain an understanding of basic electronics and their practical use in our railways.

That's the idea

I joined around 2 years ago and have found it mostly very helpful.

Polarblair

Registered

It

I'm fully tapped out this month under strict instructions from she who must be obeyed not to spend another penny but I'll look at it next month. Definitely sounds like a fantastic resource.That's the idea

I joined around 2 years ago and have found it mostly very helpful.

Polarblair

Registered

Phil is going to do us all a favour by testing out some track outdoors over winter. The two contenders are both a single track section, with wood filament crossing duckboards, one printed in ASA, and the other with PLA. Thinking about it now tough PLA would have made more sense but it will be interesting to see how well regular PLA holds up.I need to find someone who has printed in wood - infused PLA, and has a scrap print kicking about..

I know very little about the material, except it supposedly biodegrade, and might be prone to warping.. - I want to see how it takes an internal thread, and then leave it out on the patio.

Get a first-hand idea of durability.

PhilP

Polarblair

Registered

Is this by chance what you're looking for??I like the idea of a basic version which can be added to (with space for a motor etc.), and an upgrade kit to add more detail to the original. Though it's probably too big for my printer.

If there are any of those playmobil-to-lgb adapters available for 3d printing, I haven't found any free ones, if any at all.

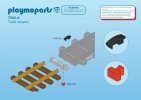

We need remakes of playmobil 7562 (the 4 pieces on the left) ideally by playmobil themselves:

The originals might have been too rare for people to have thought of reproducing them for 3d printers.

Ok, I'll admit it took longer than 5mins

I married the old and new versions of the 7562 adapter together as the compact version negated the need for removing a sleeper, but didn't have a means of locking the tracks together from what I could see.

The 7562-A is printed in ASA, lets you lock to both the brass and plastic track and has two countersunk M3 screw holes.

-bbbb

Registered

It may be. The instruction sheet is a nice touch. I only have a resin printer so I wouldn't know if I could really use it without testing it.Is this by chance what you're looking for??

Ok, I'll admit it took longer than 5mins

View attachment 318840

I married the old and new versions of the 7562 adapter together as the compact version negated the need for removing a sleeper, but didn't have a means of locking the tracks together from what I could see.

The 7562-A is printed in ASA, lets you lock to both the brass and plastic track and has two countersunk M3 screw holes.

Polarblair

Registered

playmofire

Registered

A very neat solution.

CORKYGSCALE

Registered

I am a huge fan of the 4010, with a little bit of imagination it can be a diesel or an all electric with pantographs. Currently looking at transforming one into a poor man's Glacier Express with some Panorama Express 4124 coaches. Love the work on your layout.... road, rail and sea. Errrm, you know they do airports as well !!Very pleased with the final result. Pleasantly surprised to find out the 4010 diesel fits on the turntable! Slightly less relevant given that you can't tell if it's going forwards or backwards but I still call it a win

View attachment 318559

Even if it completely dwarfs the turntable and looks a bit silly

View attachment 318560

Just barely on.

View attachment 318561

And the other end:

View attachment 318562

But larger locos have made me realise the turntable has to have some form of indexing.

Easiest way to implement would be a sprung ball bearing and detent.

The lazy susan bearing I had to hand is also far from perfect. It's partially sprung and so has some vertical movement.

So time to redesign.

Wish list:

1. Indexing.

2. Better bearing.

3. Low cost low detail version.

4. Higher price point detailed version.

5. Compatibility with motors for automation.

In terms of making it motorised what are your thoughts? Being fairly new to G scale I don't know if people have gone as far as automating RC tracks. Im assuming perhaps incorrectly that automation would only kick in for brass track. Happy to be educated.

Lastly I'm looking for criticism - anything that should be added to the wish list?