So you think this is a standard?

The words "standard" "define" and "works well enough" in the same sentence are ringing alarm bells here!

To suggest that anyone is not manufacturing to this "standard" seems a good thing to me!

Back at the beginning of our hobby there were a lot of similar products that maybe should have run together but didn't quite. So the earliest standards took all the manufacturers wheels and track measurements with an aim to improve compatibility for the least effort. Gradually over decades, and even a half century, individual manufacturers made subtle changes, and the standards evolved to include all sorts of tolerances to ensure the maximum compatibility. We're still a least another half century from having anything like a unifying standard for 45mm gauge, with a lot of standards to choose from:

Plus many more purely for the track from the same sites.

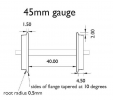

Read through a few of these and you soon get the message that its the "check gauge" and not the "back to back" that is the controlling dimension; and yes the "back to back" forms part of that dimension. Quite simply it ensures that the back of one wheel contacts the check(guard) rail before the flange of the other wheel can contact the frog.

So to "justify" the Slaters assertion that it needs small washers between the axle shoulder and back of the wheel we can have a look through the standards to see if a similar wheel exists.

A wheel that closely matches the Slaters offering appears in the Spur IIm standard S 01, but on the 32mm gauge line. This isn't a problem as the tolerances on the flange thickness have a common dimension with the 45mm gauge wheels. Note 7 of that standard basically says that if the flange is just a bit undersize that the check gauge can be maintained by a corresponding adjustment in the back to back.

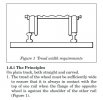

Here is a picture of a wheelset with 5mm wide wheels set to the 45mm gauge line of that standard sitting on the frog of an LGB R1 turnout. The picture is taken on the straight side for clarity, but its the same story on the curved side.

As you can see the back of the right hand wheel is nowhere need the (purely cosmetic) check rail; and don't go thinking that the check rail works with LGB wheels. Here is a picture of an LGB wheelset in the same position, again with the righthand wheel some distance from the check rail.

So why do LGB wheelsets manage to get round the diverging route when there is no contact with the check rail to prevent then colliding with and climbing up the frog?

Simple, LGB cheats, they accept that the wheels will hit the frog, so they change the shape of the frog!

Like this:

Its not an optical illusion, the tip of the frog is about 1mm out of gauge in each direction; so any measurements need to be taken from the brass rail immediately behind the frog. You can now see that when off the frog the two wheelsets pictured above actually sit 1mm further to the right.

So Fred, are LGB R1 turnouts designed for 40mm "back to back" - not even close.

Which brings us nicely back to the two solutions.

1. Attach a packing strip to all the diverging route check rails on the line to achieve the required " check gauge", as pointed out by Dunnyrail in post#13.

2. Modify the one loco by adjusting the "back to back" as dictated by the "check gauge" using the small washers on the axle. Then add larger diameter washers to thicken the back of the flange enough to negotiate the LGB turnouts.

Wow I do like the sound of my own keyboard!