Madman

Registered

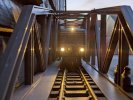

Does you neighbor know that the management of your railway is planning to lay track through the middle of their yard.....Nothing new. Just testing the new camera on my phone.View attachment 305246View attachment 305247View attachment 305248View attachment 305249View attachment 305250View attachment 305251View attachment 305252