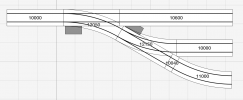

Consider a classic "yard ladder" layout, implemented using LGB R1 switches:

Two questions:

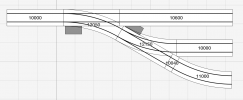

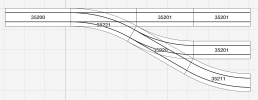

Consider the middle and lower paths through the ladder. If we start from the start of the first turnout using PIKO track, the horizontal lengths are:

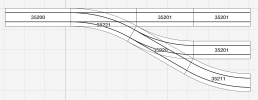

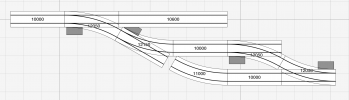

Another image with LGB track showing how left/right pairs don't match up with angled straights

Using LGB track and cutting custom lengths, a 20mm spacer on the angled turnout (bringing total straight length to 320mm) would match the vertical spacing. Aligning on the horizontal would require an extra 22.87mm.

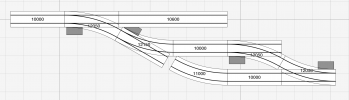

Two questions:

- what sort of clearance should I aim for between the tracks?

- 2x R1 back-to-back gives 160mm centre to centre

- a 300mm straight (as per the straight section on an LGB turnout) followed by an R1 curve gives 150mm

- adding a 41mm spacer gives 170mm

- lots of example sidings end up with 2xR1 back to back (see the curved path through the two turnouts above). However, there's a general principle that opposing curved sections should be separated by straight sections. Is there a minimum length of straight that you would recommend between the two curves?

Observations on geometry

Using basic 300mm straights, it is impossible to have a ladder layout with 160mm spacing and having the tracks all even at the end. PIKO works around this by avoiding 300mm straights and instead using 320mm + 280mm. Turnouts use a 320mm straight, which allows the vertical geometry to end up at exactly 160mm and the horizontal geometry to end up pretty close.Consider the middle and lower paths through the ladder. If we start from the start of the first turnout using PIKO track, the horizontal lengths are:

- middle path: 300 + 300 + 280 = 880mm

- 300 = 600 * sin(30)

- lower path: 300 + 277.1 + 300 = 877.1mm

- 277.1 = 320 * cos(30)

Another image with LGB track showing how left/right pairs don't match up with angled straights

Using LGB track and cutting custom lengths, a 20mm spacer on the angled turnout (bringing total straight length to 320mm) would match the vertical spacing. Aligning on the horizontal would require an extra 22.87mm.

Requirements and implementation

In practice, maintaining perfect 160mm spacing and horizontal alignment isn't required for yards which connect at only one end.- Using a ladder of junctions paired with curves maintains neat alignment, but has two serious drawbacks:

- requires a lot more horizontal space for the same number of yard branches (lose at least 300mm per branch)

- avoiding lots of opposed curves requires adding spacers

- spoils the neat alignment and spacing

- adds extra horizontal cost to every branch

- Might need extra spacers

- on first branch to avoid opposed curves

- on remaining branches if 150mm separation is insufficient clearance

- Differences in alignment are relatively minor, and can be hidden by adjusting placement of buffer stops or other features

- Visually, I don't mind if the "mainline" past the yard has a slightly different (wider?) spacing than the sidings.

- Using custom flex-track lengths avoids many of these issues