If tools are to expensive make your own, yes finally got my metal screws in different sizes.

To bad i can not post a video or a gif:

Greg Elmassian

Greg Elmassian

Thank you for your reply

Now with that picture you posted is not what i want, that is the opposite.

I found some youtube videos with that kind of "overhang" incl the big boy, sorry no...nightmare fuel, really NOT what i want.

I would like to have my aa20 as natural as it is, and i am close.

Did several experiments of what i would like and the pivoting points i mention earlier are probably the best, but the one on the back (for the wires)must be further back, more to the tender.

But oke lets do it your way: step by step, aldo i have something it is ONE machine.

But a machine has several parts that needs attention, but one can not function without the other

You mentioned the "side rods"those things that are connecting the driver wheels.

For NOW i have them attached all to each other on one unhinged strip.

It will "go" on a 4 meter radii curve, bingo!(4.5 is better performance and 5 meter radii is flawless)

The rods will have some hinged parts so that the drivers will have there 1.5mm clearance instead of being restrained with the single unhinged rod...\

When i have time i will make it like the real thing:

The unflanged wheels will have one solid rod connected with a hings to the next wheel and connect with a other hinge to the most outer wheel.

So this will give me more accurate aproge to scale modelling. instead of a gauge of 42mm i can go to probably 44mm gauge(important for frogs)

But this aside:

You see here the last 3 wheels, all 3 clearly hinged, the same applies for the first three.

But the middle three are connected with one solid rod powered by the cylinder in the middle.

This will give me a 2 -3 mm extra on gauge

Back to a other idea of you, that approach the reality in 1935 and what i wanted to do.

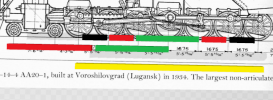

In the video's and original pictures you clearly see FOUR plates in the middle of the boiler that are supporting some of the weight of the boiler on the frame...

After looking at some artikels again i believe that there where indeed sliding, just like the front runners and the back support.

Even in model if i want a true look/appearance, i must built it this way...

It is hard to see but in the slow mo with the video you can see those four.

So I would go for the minimum of "pieces" of the frame. This will also be important when you do the rod gear, since the fewer "hinge points" the easier it will be to make the side rods. You will need to have to figure out how to add this flexibility, but making it easier to solve is good.

So it can be my option two(my paper drawing), but preferably no cuts, but the struggle of the support of the boiler with the the front runners and the back support that they can shift/move sideways under the main frame.

That the middle part of the boiler will shift left and right a bit (an inch from the centre of the track in scale).

Back to the rods, they will be all as they designed it back than, i have no choice left....

I would consider that there are 2 "driver modules" of 3 axles each. and the "central" driver would be unpowered and the 2 modules would hinge to it using a short "frame piece" that is just long enough to have the driver journals and the hinge points for your two "3 axle modules".

I dont think this is nececery, and that it can be done with one frame, i will go experiment with your first idea (like this one the most) and report back...btw the middle/central driver is unpowered

Shit.... why couldn't i find a easier to make and a good looking model....like the red devil or the DR 59 501 or...

With best regards Igor

ps "rod gear" witch one is that exactly? the one needed for speed and reverse?

Ps2 the wheels are still from abs plastic, when i figured out everything i will start casting them in zamac for live steam incl cnc and lathe in a different topic, this is just a learning curve and to get it all right before the exam.