Alan McLennan

Registered

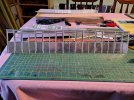

I've started back working on my scratch build Decauville 040 live steam what ever, I positioned the gas tank and made a Displacement Lubricator over the last couple of days

What a Bloke will do to save spending money on stuff he can probably make LOL, and when you spent time working and brazing up 6" table E flanges to copper pipe with a size '20' oxy tip, 1/8" and 3/16"

pipe seem real daunting to start with, but flame control is everything even with MAP gas. So here are my efforts for the last few days.. some tidying up still to come, but it's Friday and Pub O'clock. have a good one !

What a Bloke will do to save spending money on stuff he can probably make LOL, and when you spent time working and brazing up 6" table E flanges to copper pipe with a size '20' oxy tip, 1/8" and 3/16"

pipe seem real daunting to start with, but flame control is everything even with MAP gas. So here are my efforts for the last few days.. some tidying up still to come, but it's Friday and Pub O'clock. have a good one !