Not my workbench or even a bench, but I helped my friend resuport part of his railway that got damaged in the recent storms. Below you can see the damage, the plan was to replace the 2 brick pillars with wooden posts. Thankfully the line was not connected to the fence at any point, this is the prime example why you should never ever do that. In this case the damage caused was due to the fence posts rotting at ground level and the fence flapping literally in the wind like a piece of cardboard thus knocking over the posts.

View attachment 296535

The plan was to replace the brick pists now thet the fence has been replaced. However the second one had been moved to get the line somewhat right so he only wanted one new post. So a hole was dug, a metpost with post from one of the rotted at ground level suitably used after cutting to length. Some broken bricks and a bag of postcrete made things right. I was worried aboit the other brick pillar so have put some bricks round it and a bag of postcrete hoping thet it will stay secure, it all felt pretty stable before that despite the angle of dangle as it were. A bodge but hey it is his railway.

View attachment 296536

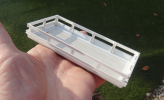

Whilst on site it would have been churlish not to run a train or two, I took my Triang Big Big Hymec with new bogies, MLS sound and Fosworks RC for a run. Bit on the slow side but very tolerant of no track power. You can see the repaired bit of line leading to Shed1 to the right. He has 2 Sheds for stock storage.

View attachment 296534

Seen below with one of his DCC 2 rail Sound Choppers. Thie Chopper found a couple of dodgy points, after 2 micro switches that supply power to the frogs replaced all was good and ready for a new season of train running. Incidentally the white line is a measure of distance in scale 1/4 miles.

View attachment 296533