You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What have you been printing.

- Thread starter mike

- Start date

3 minutes of fame

3d printing, electronics and trams

I've come to the conclusion that failing 3D printers is a highly contagious illness.

My CTC3D decided that after many, many hours of faultless printing it would royally throw its toys out of the pram and suffer the following:

Fan on RH extruder failed. Most likely wiring problem

Cable relief bracket on extruder carriage failed. Might have caused the above issue.

RH extruder totally gummed up. Stripped down and found large piece of filament stuck in exit channel

LH Extruder found to have blocked teflon tube in hot end. Very charred and carbonised. Not sure what I was printing using that side last, possibly wood. New tube fitted

SD card reader packed up. Went from slightly intermittent to not playing anymore in about 3 minutes...

Might be time to retire the old girl and replace. She's been going 7 or 8 years, including printing over 5000 mask extenders for the NHS, so probably about worn out now!!

My CTC3D decided that after many, many hours of faultless printing it would royally throw its toys out of the pram and suffer the following:

Fan on RH extruder failed. Most likely wiring problem

Cable relief bracket on extruder carriage failed. Might have caused the above issue.

RH extruder totally gummed up. Stripped down and found large piece of filament stuck in exit channel

LH Extruder found to have blocked teflon tube in hot end. Very charred and carbonised. Not sure what I was printing using that side last, possibly wood. New tube fitted

SD card reader packed up. Went from slightly intermittent to not playing anymore in about 3 minutes...

Might be time to retire the old girl and replace. She's been going 7 or 8 years, including printing over 5000 mask extenders for the NHS, so probably about worn out now!!

justme igor

Registered

You can replace a lot, but you can also look for a better printer tan you have now.SD card reader packed up. Went from slightly intermittent to not playing anymore in about 3 minutes...

Might be time to retire the old girl and replace. She's been going 7 or 8 years, including printing over 5000 mask extenders for the NHS, so probably about worn out now!!

Rebuilt rebuilt rebuilt ect it is a droid, just like a car....just like my thrusted toyota after 9 years it become to expensive....i should have kept her and do a total rebuilt.....

When i started my endeavors for 3d printing i was a whole month at you tube and sites for compartments,,,,

One printer was with head and shoulders above all....2 years ago!...the creality ender 5 plus...

One draw back if it comes and it will come....calibrating.....you are bound to do programming in gcode.....test with the robotic firmware on the printer itself....it just like gw basic in the 80's...simple.

I dont have any regrets buying this printer...

Best

Ps save youre self some money ( up to 200$) and wait 4 weeks for the delivery from ali express.

If my one would fail after 8 years and there would be no better one and fixing would be to costly i would buy this one again, not only based on reviews as a ex newbie in 3d printing...

Probaly the same but BIGGER.....500X500mm or own build---->1000x500mm.

btw what is your old printer?

3 minutes of fame

3d printing, electronics and trams

Thinking Ender 3. I really don't need anything bigger than that.

My CTC has had more updates than I can count. Power supply, fans, thermistors, sprung extruder drives, better heated bed, rewiring stepper motors, full enclosure, lighting and plenty of small repairs. Generally it's been pretty good, but I fear it's about time to say goodbye.

My CTC has had more updates than I can count. Power supply, fans, thermistors, sprung extruder drives, better heated bed, rewiring stepper motors, full enclosure, lighting and plenty of small repairs. Generally it's been pretty good, but I fear it's about time to say goodbye.

DGE-Railroad

The Orchard Line

3 minutes of fame

3d printing, electronics and trams

The good news from this neck of the woods is that the 3d printer lives! 2 fans and 1 cable replaced, SD card port is not working - can't see any obvious reason why, so I've hitched up an old laptop in the meantime to run the prints.

It's currently printing a new strain relief for the extruders, as there's a lot of cable flex there at the moment and the old one is damaged and not doing a great job.

Looking at the hours on it, it's at more than 5000 hours now, so I can't be too hard on it. Hopefully I can squeeze a little more out of it until I can afford to replace it. Track and building materials to construct the garden railway must come first however!

It's currently printing a new strain relief for the extruders, as there's a lot of cable flex there at the moment and the old one is damaged and not doing a great job.

Looking at the hours on it, it's at more than 5000 hours now, so I can't be too hard on it. Hopefully I can squeeze a little more out of it until I can afford to replace it. Track and building materials to construct the garden railway must come first however!

justme igor

Registered

Why you just dont buy pvc sheet 2 mm thick and print details on that one?Another day down the Pub, that's 2Kgs of PETG used so far in this oneI should probably buy some buildings it's going to take forever to print the whole village

there's a little bit of playmoil still in it, just not a lot anymore.

Or only print details and glue them om a pvc sheet......

Oh yes printing can be a very expensive hobby....but a lot...if not 80% of the costs can be taking away if you think a bit out of the box......

Oke granted you must pay for xt pvc sheet 2mm and you must paint it....or buy foam pvc sheet 2mm in color, both let you glue with pvc glue( read solvent) the fine printed details on them.....

Oke a bit more work, but 80% cost wise?...penny saved pond wise( i know the original saying).....

With best regards Igor

justme igor

Registered

Clever thinking really clever....hmmmm got one for spare, thanks for the tip......but fine tune your printer will cost more time now, but will save you tremendous amounts of time in the near future, believe me i know what i am talking about.....Today’s little print allows me to mount Proxxon sanding pads to the end of an electric toothbrush to help sand those difficult to reach areas of other 3D printed parts

ge_rik

British narrow gauge (esp. Southwold and W&LLR)

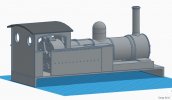

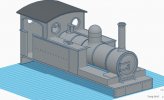

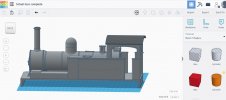

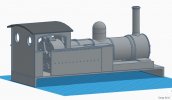

My latest project. I wasn't happy with the Bachmann Lyn I recently purchased. The scale is wrong (13.8mm/ft) and the outswing is too much on my tight curves so I found a rather nice looking 440T which ran on the Schull & Skibbereen Railway. I've decided to adapt the Lyn chassis to 044T similar to another Schull loco as it had outside frames like Lyn.

The body was drawn in TinkerCAD and I'm about half way through printing out the bits.

I'm hoping t test run her later in the week (weather permitting)

Rik

The body was drawn in TinkerCAD and I'm about half way through printing out the bits.

I'm hoping t test run her later in the week (weather permitting)

Rik

Rhinochugger

Retired Oik

I would have thought that a 4-4-0 would have a fair bit of swing - more than a 2-4-2 possibly

ge_rik

British narrow gauge (esp. Southwold and W&LLR)

Much less at the front and probably about the same at the back - but my cunning plan is to mount the coupling on the bogie at the rear.I would have thought that a 4-4-0 would have a fair bit of swing - more than a 2-4-2 possibly

Rik

What scale you using 15mm to the foot?My latest project. I wasn't happy with the Bachmann Lyn I recently purchased. The scale is wrong (13.8mm/ft) and the outswing is too much on my tight curves so I found a rather nice looking 440T which ran on the Schull & Skibbereen Railway. I've decided to adapt the Lyn chassis to 044T similar to another Schull loco as it had outside frames like Lyn.

The body was drawn in TinkerCAD and I'm about half way through printing out the bits.

View attachment 280250View attachment 280251View attachment 280252View attachment 280253

I'm hoping t test run her later in the week (weather permitting)

Rik