Well I can accurately say exactly what I've been printing today. Nothing at all!

I'm starting to wonder if such a thing as The Cursed Print exists... Four times now I've tried to print the same set of coach bogies. Each time it's a 15h print in super detail. Each time there's also been prep work in getting custom supports put in for them.

The first 2 times, our main circuit tripped over night thanks to the torrential rain we've had finding its way into an outside socket.

The third time I inadvertently caught the USB cable sending the Gcode to the printer and couldn't find a way to convince Cura to continue the print.

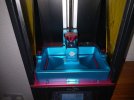

The fourth and final time, the hotend and/or thermister left the building at some point overnight and the print failed about 12h in. Gargh!

After clearing out the filament from the Bowden tube, I brought the hotend up to temp in the display and tried extruding a few mm of filament as I'd usually do, to prime everything. Nothing. The extruder was trying to push the filament, the display said it was at it's 208c target but the hotend seemed cold.

This struck me as strange. Thermisters sometimes go, but I'd expect it to think the hotend was at zero, not my requested temperature!

power everything down. Go and have a cup of coffee, power it all up and try again. Same.

Dug out an IR thermometer which confirmed the hotend was cold. The printer was still convinced it had reached temperature.

At this point I decided to rule out the wiring and board, given I'd recently upgraded the motherboard. I put a voltmeter across the hotend feed and told it to heat. Sure enough, 24v appeared.

Gave up and ordered a hotend/thermistor/capricorn Bowden tube package from Amazon, then sulked as I couldn't print for another 24h