Rhinochugger

Retired Oik

Is there any difference between 3D printing and cake icing ?Rik,

Would that be a 0.4mm nozzle?

I think 4mm is for icing cakes?

Is there any difference between 3D printing and cake icing ?Rik,

Would that be a 0.4mm nozzle?

I think 4mm is for icing cakes?

What are you going to go for, cup cakes ?I am paying attention, one day I may even get round to having a go at 3D Printing. After all I finally got round to trying out Deltang and LiPo’s.

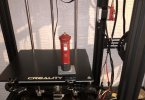

Took me a while to take the plunge - but certainly not regretting it. I'm already writing to Santa for an improved modelI am paying attention, one day I may even get round to having a go at 3D Printing. After all I finally got round to trying out Deltang and LiPo’s.

Why, is that how Santa makes all those toys ?Took me a while to take the plunge - but certainly not regretting it. I'm already writing to Santa for an improved model

Rik

Rik, you could print the sides thinner and stick them together. though after watching the vid (which I found interesting (sad eh)) there seems numerous was of alleviating the elephants foot, for your wagons I would think the chamfer would be easiest,My latest project has been to replicate the open wagons which I constructed from my own resin castings. I was interested in how a 3D printed version might compare. The originals used Hartland Loco Works mini-series wagon chassis which, at the time, could be picked up for less than £10 each. They have now ceased production and so I have produced my own version which uses the same dimensions but has more appropriate W-iron leaf spring suspension than the HLW version. Still a bit more tweaking to be done - the internal planking disappears because, I am reliably informed, of the 'elephant's foot effect' so I need to compensate for that. But, I'm quite pleased with the outcome. All drawn in TinkerCAD BTW.

Rik

Hi RickyHow long did the total print take compared casting one from resin? Did you print it all as one solid piece, or as a 'kit' like with the resin original?

How about Sadie as in Happy Sadie my printing lady?Hi Ricky

No, I've printed the parts separately, as with the original 'kit'.

The base took the longest to print (around 12 hours). The solebars each take around 4 hours, each side is just over four hours and each end around 3 hours - so total print time is circa 34 hours. That's not counting how long it took to draw the parts in TinkerCAD

Not sure how long it took to resin cast each wagon. Of course, I was only casting the sides and ends (not the base or solebars). The resin took about 15 minutes to reach the stage where it could be removed from the mould. I cast one end and one side at a time - so around an hour to cast each body (the resin needs time to harden) compared with 14 hours to 3D print the body. Probably, the construction of the masters for the mould and then the casting of the mould probably took slightly longer than it did to make the drawings. So, overall, resin casting is quicker in time - but messier (and smellier) and more expensive.

I much prefer 3D printing. The finish is better, the process more satisfying and I am able to tweak the drawings between each print if I decide to change something or add more detail. Once the printer has been set off and running, I can happily get on with something else. In fact, it's quite therapeutic having the printer whirring quietly in the background - almost like having a fellow modeller in the workshop.

Rik

PS - No, I haven't given my printers names (yet!)